We are excited to announce BEAM v1.1 is ready!

Your building's carbon footprint, made easy.

Increasingly building professionals want to know: what is the carbon footprint of my building materials? And how can I reduce those impacts?

We've built the BEAM estimator to help answer these questions, and we've made it easy to use and understand. BEAM contains a comprehensive list of materials/products complete with their carbon footprints. Whether you're modeling an assembly or an entire building, BEAM provides accurate and up-to-date information in real-time, accompanied by informative reports. Start gaining valuable, data-driven insights into carbon reduction strategies with the BEAM estimator! |

Here's what our users have to say!

/

- 1

- 2

- 3

- 4

- 5

What impressed me most using the BEAM estimator tool is how intuitive and adaptable it is, making it easy to incorporate carbon accounting into a project's workflow from the first sketches to the final build. With the BEAM tool, I was never dealing with parameters outside of my wheelhouse as a designer, which made it both approachable and empowering. Further simplifying the process, the inputs required for the tool are available from schematic design, can be automatically generated by most modeling or documentation tools and are easily adaptable as the project changes throughout the design process. The BEAM tool easily provided me with a clear snapshot of the impact of three projects, all in different stages of design, and quickly highlighted areas of improvement making it obvious how to cut carbon here and now.

Livia Barrett

Designer

/ Forge Craft Architecture + Design

- 1

- 2

- 3

- 4

- 5

/

- 1

- 2

- 3

- 4

- 5

Just wanna say how incredibly awesome this tool is!

We used the carbon calculator tool to help us identify the best assemblies for a 20,000 sf institutional building on a short timeline. It was incredibly easy and fast to plug in a square footage and R value which eliminates the variability of thermal performance. Within 30 minutes, we could identify which assemblies would have the most carbon storing potential. We then incorporated cost feedback from contractors to inform clients with real data and guide them to meet their goals.

We used the carbon calculator tool to help us identify the best assemblies for a 20,000 sf institutional building on a short timeline. It was incredibly easy and fast to plug in a square footage and R value which eliminates the variability of thermal performance. Within 30 minutes, we could identify which assemblies would have the most carbon storing potential. We then incorporated cost feedback from contractors to inform clients with real data and guide them to meet their goals.

Lindsay Love

Principal

/ Love Schack Architects

- 1

- 2

- 3

- 4

- 5

/

- 1

- 2

- 3

- 4

- 5

The BEAM tool is the missing ingredient our industry needs to move forward with verifiable low carbon construction.

Lucas Johnson

Managing Director

/ Vali Homes

- 1

- 2

- 3

- 4

- 5

/

- 1

- 2

- 3

- 4

- 5

We’ve used the BEAM Calculator to assess the carbon implications of our material choices for several of our projects, and it’s fascinating to discover what the biggest emitters as well as the biggest storage opportunities are. The BEAM Calculator is the right-sized tool for most small to mid-scale projects, which are the majority of those built.”

/

- 1

- 2

- 3

- 4

- 5

Super intuitive and extremely informative! I think it's exactly the tool we need -- not cumbersome to adopt at all. Showing both the total kgCO2e and kgCO2e/m2 is really useful to compare across different projects.

Michele Deluca

Energy Advisor

/ 3 west Energy Building Consultants

- 1

- 2

- 3

- 4

- 5

/

- 1

- 2

- 3

- 4

- 5

The BEAM tool has been incredibly useful and easy to use. I think you all have nailed it in terms of providing a tool that provides detailed information but allows for quick iteration.

Rob Williams AIA

Assistant Professor

/ UMass Amherst

- 1

- 2

- 3

- 4

- 5

/

- 1

- 2

- 3

- 4

- 5

This is the tool that those passionate about great environmental residential construction have been waiting for. Being able to evaluate the embodied carbon performance of our buildings will take its rightful place alongside evaluation of their operational performance. BEAM will help us determine where to invest the next dollar to yield the highest carbon performance return.

Marc Rosenbaum

Principal

/ South Mountain Company

- 1

- 2

- 3

- 4

- 5

/

- 1

- 2

- 3

- 4

- 5

Once we were enlightened to the fact that we'd been barking up the wrong tree all along- that our real focus should be on Carbon not merely energy- we found ourselves lost in the woods. We knew what our focus should be, but we needed a tool to help us metric the actual planetary impact of our projects. Enter the BEAM tool. Clear, easy to use (even for an architect :-), and effective. This tool is a game changer. Highly recommended.

Michael Klement AIA CPHC

/

/ Architectural Resource, LLC

- 1

- 2

- 3

- 4

- 5

/

- 1

- 2

- 3

- 4

- 5

Using the beta-version of the BEAM calculator on some Passive House buildings was enlightening. The simplicity of this calculator and the extensive (and growing) number of EPDs incorporated in it make this a highly effective tool to help drive down embodied carbon in new homes.

/

- 1

- 2

- 3

- 4

- 5

The BEAM tool arrived at a moment of profound anthropocentric reflection in the academic sector. It has enormously helped my colleagues and students in their early careers. UMass-Amherst students from the Architecture department and the Building and Construction Technology program have been making critical decisions in their projects (actual buildings!) about materials use through the estimations and the environmental education provided by the tool (I love its Glossary section). It is an incredibly transparent, pedagogical, and easy-to-use tool.

Diana Andrea Brito Picciott

Ph.D. Candidate

/ University of Massachusetts Amherst

- 1

- 2

- 3

- 4

- 5

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

What we love about BEAM

|

Easy to use

Designed to be intuitive and quick to learn |

Simple material selection

Click the checkbox to make material selections |

Identify high emitters

Spot the materials with high climate impact |

Green options

Find alternative materials alongside conventional |

|

Compare materials

See comparative side-by-side results |

Set and meet goals

Match carbon footprint of building with climate goals |

Shareable reports

Get results in the hands of clients and teammates |

Baseline vs improvements

Create a whole-house baseline and alternatives |

BEAM helps you make informed,

climate smart choices!

Take a peek inside...

Learn how to use BEAM v1.1

There's no better way to learn how to use BEAM than from the team that built it! Our interactive, online course is delivered over three 1.5hr sessions and will help master BEAM.

Upon completion of this course, you'll possess a strong understanding of embodied carbon accounting and how to integrate it into your professional practice! Our next course in June is open for registration!

|

Get your copy of BEAM v1.1

|

|

Why is BEAM not behind a paywall?

After much discussion, we decided that BEAM would have the broadest impact if we did not put it behind a required paywall. The pay-what-you-can model allows a broad range of users to access the tool, aligning with our commitment to inclusivity and ensuring that sustainability practices are accessible to all, regardless of financial resources. |

|

|

This means we will be relying on user support!

BEAM was created and is maintained by a passionate, small team. User support is fundamental for the ongoing maintenance and development of the tool. We have lots of plans for improvements and expansions for BEAM in the future, and we hope that BEAM users will provide us with the financial contributions we need to continue developing this tool. |

FAQ

Is BEAM the right tool for me?

If you are wanting to know the carbon footprint of the materials in your building and make easy comparisons between different materials and assemblies, then BEAM is for you. You can use BEAM to simply compare the carbon footprint of materials within a particular category, or easily create assemblies and whole building models. BEAM quickly and easily shows you where your “carbon hotspots” are and helps you identify the best ways to reduce emissions from your projects.

What kind of buildings can I model in BEAM?

BEAM is made for the low- and mid-rise residential sector. If you build homes, or commercial/institutional buildings then BEAM is designed to include all the major materials and assemblies you are using.

Why use BEAM instead of another carbon tool?

Each tool on the market is intended to offer specific information about a specific type of building. BEAM is made for users in the low- and mid-rise sector and is intended to be used by people with no background in life cycle assessment, but who understand materials and assemblies. BEAM shows users comparative information in a very quick and easy format. In a short amount of time, with just a minimum of instructions, BEAM can show you how and where you can make a major difference in the carbon footprint of your building projects.

BEAM is currently the only tool on the market that uses a consistent approach to calculating the impacts of carbon storage in building materials. We see this as a critically important consideration and worked to develop a carbon storage methodology that is science-based and transparent.

BEAM is currently the only tool on the market that uses a consistent approach to calculating the impacts of carbon storage in building materials. We see this as a critically important consideration and worked to develop a carbon storage methodology that is science-based and transparent.

Can I use BEAM for renovations or only new construction?

BEAM can be used for renovation projects. BEAM users select all the materials they will be using for a project, and it doesn’t matter if the project is a small update to a single room, an energy retrofit or a new multi-unit building. We hope renovators will make use of the easy material comparisons in BEAM for whatever categories of materials will be used.

Why is BEAM an estimator vs calculator?

The data used in BEAM can be compared to the fuel-mileage ratings, which are very good for making comparisons between different products/models but rarely reflect the actual mileage from driving the car because the rating is measured using a very particular set of driving conditions. As with fuel-mileage ratings, BEAM users can accurately compare the scale of climate impacts between materials, assemblies and whole buildings, but not calculate an accurate emission count.

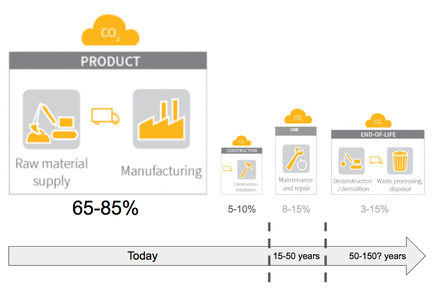

What life cycle phases does beam cover?

BEAM is a “cradle-to-gate” estimator, meaning that we include all emissions associated with turning raw materials into building products (phases A1-A3, for life cycle assessment nerds!). We choose this focus because this is where the vast majority of life cycle emissions occur for building products and they have an immediate impact on our climate. At this product level, we hope to empower BEAM users to make the biggest impact in the place on the life cycle where we have the most leverage. See our BEAM methodology section to learn more.

What is not included in BEAM calculations?

BEAM includes all of the major structural, enclosure and partition materials (foundations, walls, floors, roofs, windows, and cladding materials). This represents the majority of the mass of materials in a building project.

Not included (at least not yet) are mechanical, plumbing and electrical materials; paints and surface finishes; stairs, cabinetry and millwork; and decks and exterior yardworks. In most cases, we simply don’t have enough reliable data to include these materials.

Not included (at least not yet) are mechanical, plumbing and electrical materials; paints and surface finishes; stairs, cabinetry and millwork; and decks and exterior yardworks. In most cases, we simply don’t have enough reliable data to include these materials.

If I agree to have anonymized versions of my BEAM models collected, what will you be doing with it?

We are asking permission to use anonymized versions of your completed building models in order to grow our understanding of material emissions and to help provide benchmark averages and material “hot spots.”

We do not have access to your working models and we cannot follow or trace your activities in BEAM. It is only when you indicate that a project is complete that we import an anonymized version of your model.

Please see our EULA and Privacy Policy in our footer below.

We do not have access to your working models and we cannot follow or trace your activities in BEAM. It is only when you indicate that a project is complete that we import an anonymized version of your model.

Please see our EULA and Privacy Policy in our footer below.

How often will BEAM be updated?

We will update BEAM as often as we are able. Our current business model is funded by user contributions and we’ll be able to improve BEAM based on the status of our funding.

Does BEAM run on MAC or PC?

BEAM is a web-based software, all you need to access BEAM is a web browser and internet connection.

Can I open BEAM in Excel?

No, for BEAM to function properly you can ONLY use BEAM in Google sheets.

Can I use BEAM offline or do I need an internet connection?

You will need and internet connection to use BEAM since it is a cloud based software.

Can our team share one copy of BEAM?

Yes, after you get your copy of BEAM you can share the file with others so that you can collaboratively work on projects. Please see details on how to share in our User Guide after you sign-up.

Does it integrate with other programs, such as design or energy modeling software?

Currently, BEAM is a stand-alone software. Integrations with popular software products are high on the list of next steps for BEAM.

Where does the information in BEAM come from?

Can I get support if I am having issues?

Yes, once you are logged into your BEAM copy, we do have a support email.

BEAM Methodology...

We built BEAM to be easy to use and understand, but behind the scenes we held ourselves to rigorous standards in our methodology. We also made some decisions that result in this tool being different from others in the market.

BEAM is based on a methodology common for embodied carbon calculations. The Global Warming Potential (GWP) factors for materials are gathered from Environmental Product Declarations (EPDs), which are third-party certified reports prepared according to ISO 14025 in addition to either EN 15804 or ISO 21930: 2017. Where no EPDs exist for a product, BEAM uses an average GWP result from all applicable peer-reviewed life cycle assessments (LCAs) of the product.

GWP factors are quantities of GHG emissions arising from specific life cycle stages, expressed in kilograms of carbon dioxide equivalent (kg CO2e) per given “functional unit” of a material or product (e.g. 1 m3, 1 kg, 1 m2 , depending on the product).

The GWP factors in BEAM are a sum of life cycle stages A1 (raw material acquisition), A2 (transportation of raw materials to manufacturing facility) and A3 (manufacturing emissions). This is often referred to as a “cradle to gate” analysis and makes up the “material carbon emissions” (MCE).

BEAM is based on a methodology common for embodied carbon calculations. The Global Warming Potential (GWP) factors for materials are gathered from Environmental Product Declarations (EPDs), which are third-party certified reports prepared according to ISO 14025 in addition to either EN 15804 or ISO 21930: 2017. Where no EPDs exist for a product, BEAM uses an average GWP result from all applicable peer-reviewed life cycle assessments (LCAs) of the product.

GWP factors are quantities of GHG emissions arising from specific life cycle stages, expressed in kilograms of carbon dioxide equivalent (kg CO2e) per given “functional unit” of a material or product (e.g. 1 m3, 1 kg, 1 m2 , depending on the product).

The GWP factors in BEAM are a sum of life cycle stages A1 (raw material acquisition), A2 (transportation of raw materials to manufacturing facility) and A3 (manufacturing emissions). This is often referred to as a “cradle to gate” analysis and makes up the “material carbon emissions” (MCE).

|

Why focus on material-related emissions?

BEAM is different from life cycle assessment software programs, because we only provide material carbon emissions results. Why choose to focus just on these up-front impacts and not the whole life cycle? We felt there were some very compelling reasons:

|

|

BEAM counts carbon stored in bio-based materials

BEAM accounts for carbon storage in products that contain biogenic materials sourced from agricultural or forestry residues and recycling streams. In such cases, the mass of biogenic material per functional unit is determined according to the product EPD or LCA and the mass of carbon within that biogenic material is calculated based on chemical composition analysis results from the Phyllis database17. The net GWP emissions for the product is the result of the A1-A3 carbon emissions minus the biogenic carbon storage. The net emissions for some biogenic materials therefore have a negative value when carbon storage is greater than carbon emissions. These net negative emissions materials are often termed “carbon-storing” materials.

BEAM does not attribute carbon storage to virgin timber products. While there is a standard methodology in ISO 21930 for determining biogenic carbon storage credits for products, there remain important and unresolved concerns with current accounting methods related

to virgin forest products like lumber. Some of these concerns include uncertainty about the amount of carbon released from soils during logging operations; the amount of carbon returning to the atmosphere from roots, slash and mill waste; the amount of carbon storage capacity lost when a growing tree is harvested; and the lag time for newly planted trees to begin absorbing significant amounts of atmospheric carbon dioxide. These factors and others are being researched and deliberated by experts from academia, the forestry industry, the building industry, environmental advocacy organizations, and LCA professions. Because these critical issues were unresolved at the time of this study, the BEAM version used for the study excluded biogenic carbon storage for products made of raw logged timbers (including framing lumber, plywood, OSB and wood trusses and I-beams).

BEAM counts the structure, enclosure and partition materials

BEAM focuses on the structure, enclosure and partition assemblies. These sections of the building make up the majority of the material mass and have typical lifespans of 20-80 years, covering the decades in which we must meet GHG mitigation targets. BEAM does not include mechanical, electrical or plumbing (MEP) materials, due to a lack of good data. Fixtures, appliances, millwork, stairs, paints and surface finishes are excluded due to lack of data and/or lack of meaningful substitutions. Decks, driveways and site work are also excluded.

Built-in material take-offs

BEAM calculations begin with entering the relevant building dimensions from the plan set, which are then used as the basis for calculating material quantity estimations. Fields are provided in BEAM to further specify key dimensions and factors used to complete quantity estimations, such as R-value for insulation, framing spacing, and concrete wall and floor thickness.

User selected materials

With all material quantity information entered, BEAM provides the GWP for every material option in a given assembly. The user can select the desired product (or an average emission result) and BEAM counts the results toward an assembly subtotal and a total for the whole building.

Evolving methodologies

The BEAM team has decided on a particular methodology, as summarized here. There is a great deal of work happening in the LCA world, and we will continue to participate in these discussions and bring developments and changes to BEAM as they evolve.

BEAM accounts for carbon storage in products that contain biogenic materials sourced from agricultural or forestry residues and recycling streams. In such cases, the mass of biogenic material per functional unit is determined according to the product EPD or LCA and the mass of carbon within that biogenic material is calculated based on chemical composition analysis results from the Phyllis database17. The net GWP emissions for the product is the result of the A1-A3 carbon emissions minus the biogenic carbon storage. The net emissions for some biogenic materials therefore have a negative value when carbon storage is greater than carbon emissions. These net negative emissions materials are often termed “carbon-storing” materials.

BEAM does not attribute carbon storage to virgin timber products. While there is a standard methodology in ISO 21930 for determining biogenic carbon storage credits for products, there remain important and unresolved concerns with current accounting methods related

to virgin forest products like lumber. Some of these concerns include uncertainty about the amount of carbon released from soils during logging operations; the amount of carbon returning to the atmosphere from roots, slash and mill waste; the amount of carbon storage capacity lost when a growing tree is harvested; and the lag time for newly planted trees to begin absorbing significant amounts of atmospheric carbon dioxide. These factors and others are being researched and deliberated by experts from academia, the forestry industry, the building industry, environmental advocacy organizations, and LCA professions. Because these critical issues were unresolved at the time of this study, the BEAM version used for the study excluded biogenic carbon storage for products made of raw logged timbers (including framing lumber, plywood, OSB and wood trusses and I-beams).

BEAM counts the structure, enclosure and partition materials

BEAM focuses on the structure, enclosure and partition assemblies. These sections of the building make up the majority of the material mass and have typical lifespans of 20-80 years, covering the decades in which we must meet GHG mitigation targets. BEAM does not include mechanical, electrical or plumbing (MEP) materials, due to a lack of good data. Fixtures, appliances, millwork, stairs, paints and surface finishes are excluded due to lack of data and/or lack of meaningful substitutions. Decks, driveways and site work are also excluded.

Built-in material take-offs

BEAM calculations begin with entering the relevant building dimensions from the plan set, which are then used as the basis for calculating material quantity estimations. Fields are provided in BEAM to further specify key dimensions and factors used to complete quantity estimations, such as R-value for insulation, framing spacing, and concrete wall and floor thickness.

User selected materials

With all material quantity information entered, BEAM provides the GWP for every material option in a given assembly. The user can select the desired product (or an average emission result) and BEAM counts the results toward an assembly subtotal and a total for the whole building.

Evolving methodologies

The BEAM team has decided on a particular methodology, as summarized here. There is a great deal of work happening in the LCA world, and we will continue to participate in these discussions and bring developments and changes to BEAM as they evolve.

Thank you to our BEAM v1.1 Sponsors

Their belief in our mission and their generous contributions were instrumental in successfully launching BEAM V1.1. We can't thank them enough for their generosity and hope that you consider supporting them in return.